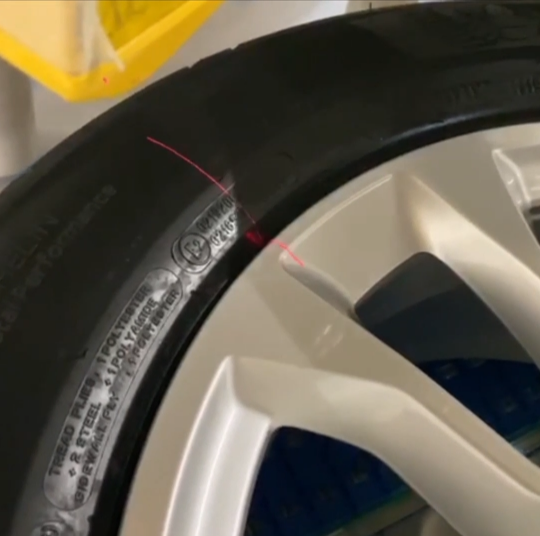

To read the DOT code engraved on a tire and check the right wheel/tire assembled set requires an automatic machine that is able to decode the DOT code of the tire and verify the shape and color of the wheel paired. This is obtained using profilometers as vision sensors, suitable to acquire profile from the surface of the tire (rubber with black-on-black lettering), a matrixial RGB camera, to read the shape and the color of the wheel, and customized software to reconstruct shoulder’s 3D surface, decode and recognize the characters of DOT code, the shape of the wheel and verify the right coupling of the wheel/tire assembled set, according the attended value transmitted to the machine from customer’s MES.

The machine is equipped with a centering tools, that positions the wheel/tire on the center of the conveyor, and a rotating system that turns the wheel/tire set of 360 degrees, to allow the scanning of the area where is engraved the DOT code: the profilometer will positioned in the right positions on the Upper side of the tire, according to the dimensions of the wheel/tire set to process.

Tires of different Rim, Out Diameters and Tread’s height can be processed on the machine.

The machine can be equipped with two profilometers, according to customers requirement, to read the DOT code on the Upper side and Lower side of the wheel/tire assembled set.